300bar Carbon Fiber Scba Breathing Apparatus Cylinder

Brand: Snow Rain

Product origin: Shenyang, Liaoning

Delivery time: 7~10 days

Supply capacity: 400,000 pieces/year

1. Our cylinder scba is not only light in weight and high in strength, but also has good safety performance.

2. Our cylinder scba is impact-resistant and wear-resistant.

3. The bottle valve of our breathing apparatus cylinder has a high-pressure safety protection device.

Introduction of 300bar Carbon Fiber Scba Breathing Apparatus Cylinder:

SCBA cylinder is a key piece of equipment specially designed to provide respiratory support and is suitable for emergency rescue, firefighters, special working environments and other occasions. This scba cylinder is popular for its high strength, high-pressure gas storage capacity and compliance with strict safety standards. The scba cylinder is a key device to ensure the safety of workers in emergency rescue and special working environments. The scba cylinder provides users with reliable respiratory support and protection.

Advantages of breathing apparatus cylinder:

1. Due to its light material, cylinder scba is relatively light in weight and easy to carry and use.

2. The cylinder scba is made of carbon fiber and glass fiber, which has good impact resistance and wear resistance and long service life.

3. The cylinder scba has a high-pressure safety protection device, which can effectively prevent the cylinder from exploding under high pressure.

4. Our scba cylinder is made of environmentally friendly materials and has no pollution to the environment.

5. Our scba cylinder uses an anti-corrosion aluminum alloy liner, which can effectively prevent gas from corroding the cylinder.

7. Our scba cylinder valve is simple in design and easy to maintain and replace.

Breathing apparatus cylinder specifications:

| SCBA and EEBD Gas Cylinder Tehnical Data Sheet | |||||

| Specification/Model | Volume(L) | Outside Diameter(mm) | Length(mm) | Weight(kg) | Working Pressure(bar) |

| CRPIII-93-0.8-30-T | 0.8 | 101 | 200 | 0.7 | 300 |

| CRPIII-93-1.12-30-T | 1.12 | 101 | 250 | 0.9 | 300 |

| CRPIII-88-2.0-30-T | 2 | 106 | 383 | 1.9 | 300 |

| CRPIII-120-2.5-30-T | 2.5 | 129 | 310 | 1.6 | 300 |

| CRPIII-124-2.7-30-T | 2.7 | 132 | 310 | 1.7 | 300 |

| CRPIII-105-3.0-30-T | 3.0L | 113 | 453 | 2.2 | 300 |

| CRPIII-124-4.7-30-T | 4.7L | 137 | 495 | 3.5 | 300 |

| CRPIII-144-6.8-30-T | 6.8L | 158 | 528 | 3.9 | 300 |

| CRPIII-162-9.0-30-T | 9.0L | 176 | 562 | 5.2 | 300 |

| CRPIII-192-12-30-T | 12 | 208 | 575 | 6.5 | 300 |

| CRPIII-192-20-30-T | 20 | 208 | 840 | 9 | 300 |

| Specification/Model | Volume(L) | Outside Diameter(mm) | Length(mm) | Weight(kg) | Working Pressure(bar) |

| CRPIII-106-2.0-20-T | 2 | 113 | 330 | 1.4 | 200 |

| CRPIII-120-2.5-20-T | 2.5 | 127 | 309 | 1.6 | 200 |

| CRPIII-106-3.0-20-T | 3 | 113 | 465 | 2 | 200 |

| We can manufacture aluminum gas cylinder from 0.19L to 200L, for other carbon fiber gas cylinders blow 1L, please visit our PCP Tank And Paintball Tank category. We can also manufacture other specifications as per requirement. Please feel free to contact us for inquiry. | |||||

Purpose of SCBA cylinder:

SCBA cylinder can be used in firefighting, emergency rescue, chemical industry, mining, petroleum, shipbuilding, metallurgy, electricity, pharmaceutical, nuclear energy, rescue teams and dangerous working environments. Cylinder scba is a high-pressure, lightweight and portable gas storage equipment. Cylinder SCBA is used in conjunction with self-contained breathing apparatus to provide clean and breathable compressed air for personnel in dangerous environments such as toxic, harmful, hypoxic or smoky environments.

Use of breathing apparatus cylinder:

When using SCBA cylinder, strictly follow the relevant standard operating procedures. Before officially using cylinder SCBA, check whether the bottle body of breathing apparatus cylinder has cracks, wear, bulges or corrosion. Also check whether the bottle valve of SCBA cylinder is intact and not loose, and whether the pressure gauge pointer is in the green area. Then connect the pressure regulator tightly with the breathing system of cylinder SCBA, and make sure that the pressure regulating system is in the closed state before opening the bottle valve. When opening the valve of the breathing apparatus cylinder, the valve hand wheel should be rotated slowly. After there is no abnormality, you can start wearing the SCBA device. First, tie the back-carrying gas cylinder system to the back, then wear the mask in turn and adjust the elastic band to ensure good airtightness. After opening the valve to supply gas, you should take a test breath to see that the gas flows smoothly and there is no fog or leakage in the mask. After use, the SCBA cylinder valve should be closed to release the remaining gas, disassemble the connection parts between the pressure regulator and the breathing apparatus. And cylinder scba clean the surface of the cylinder SCBA with a special cloth.

FAQ:

Q: What material is the SCBA cylinder made of?

A: Our SCBA cylinder is made of lightweight, high-strength carbon fiber composite material with good pressure resistance and corrosion resistance.

Q: What scenarios are cylinder SCBA suitable for?

A: Our cylinder SCBA can be widely used in dangerous environments such as firefighting, petrochemicals, mine rescue, ships, high-rise escape, toxic gas operations, etc.

Q: Can the cylinder SCBA be inflated and used repeatedly?

A: Yes, the cylinder can be inflated and used multiple times after compliance testing and maintenance.

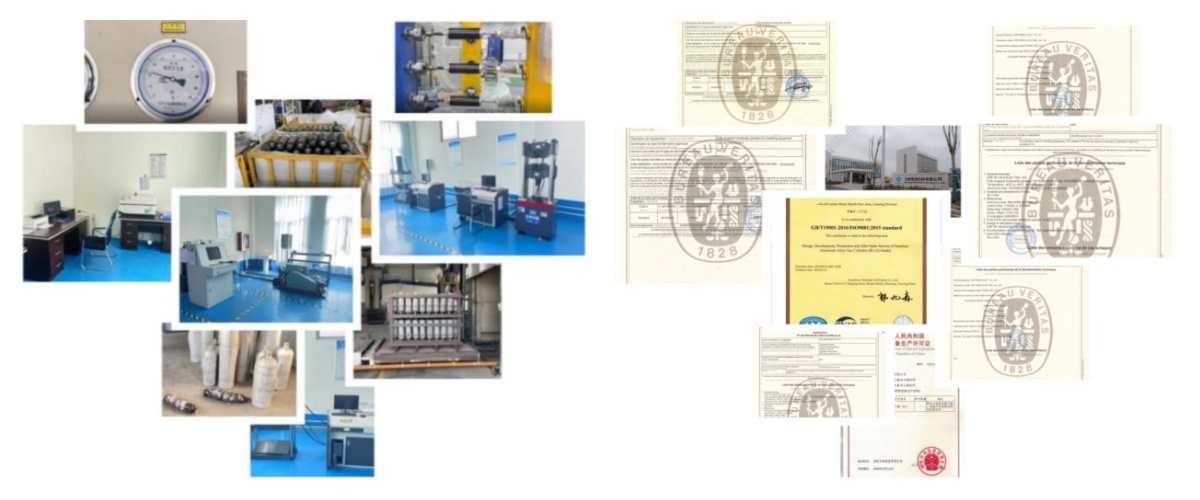

About Us:

We focus on the research and development and manufacture of high-quality cylinder breathing apparatus (SCBA). Each set of products has been strictly designed and tested. The respirator is made of high-strength carbon fiber composite materials, which not only reduces the overall weight, but also improves the pressure resistance and impact resistance. The products strictly follow international safety standards and industry specifications and are widely used in fire protection, chemical industry, mining, shipbuilding and other fields. We also provide flexible customization services, which can adjust the cylinder capacity, working pressure, interface mode and overall structure according to customer needs to ensure that the equipment is fully adapted to different application scenarios.