How Do Differences in PCP Air Cylinder Weight Affect the Shooting Experience?

Different materials result in different cylinder weights.

The weight of a PCP air cylinder largely depends on the density of the material and its structural design. While steel cylinders are structurally robust, they inevitably result in higher weight, while aluminum alloy cylinders offer a lightweight advantage at the material level. Snowrain chooses 6061A high-strength aluminum alloy as the main raw material for its Aluminum PCP Air Cylinders. Through mature molding and processing techniques, the overall weight of the cylinder is effectively controlled while ensuring pressure resistance, making the aluminum alloy PCP air cylinder more flexible in practical use.

Weight differences affect the shooting process.

In PCP shooting, the air cylinder is usually located at the rear or bottom of the gun body and is one of the heaviest components. When the cylinder is heavy, prolonged shooting can easily increase the burden on the arms and shoulders, and it becomes more difficult to maintain a stable shooting posture. In contrast, the reduced weight of aluminum alloy PCP air cylinders improves the balance of the entire gun, making it easier to handle. Snowrain optimized the structural design of its Aluminum PCP Air Cylinders based on these real-world usage scenarios and ensured stable performance through rigorous testing.

Weight differences are amplified after prolonged use.

In short-term use, the weight difference may not be obvious, but as shooting time increases or training frequency increases, this difference will gradually become more pronounced. Many users only clearly feel the advantages of lightweight design after continuous use. In its cooperation with OEM and custom clients, Snowrain usually recommends the most suitable Aluminum PCP Air Cylinder configuration based on usage frequency and application scenarios, and ensures consistency in weight and performance across different batches through stable mass production capabilities.

Lightweight design does not mean sacrificing safety.

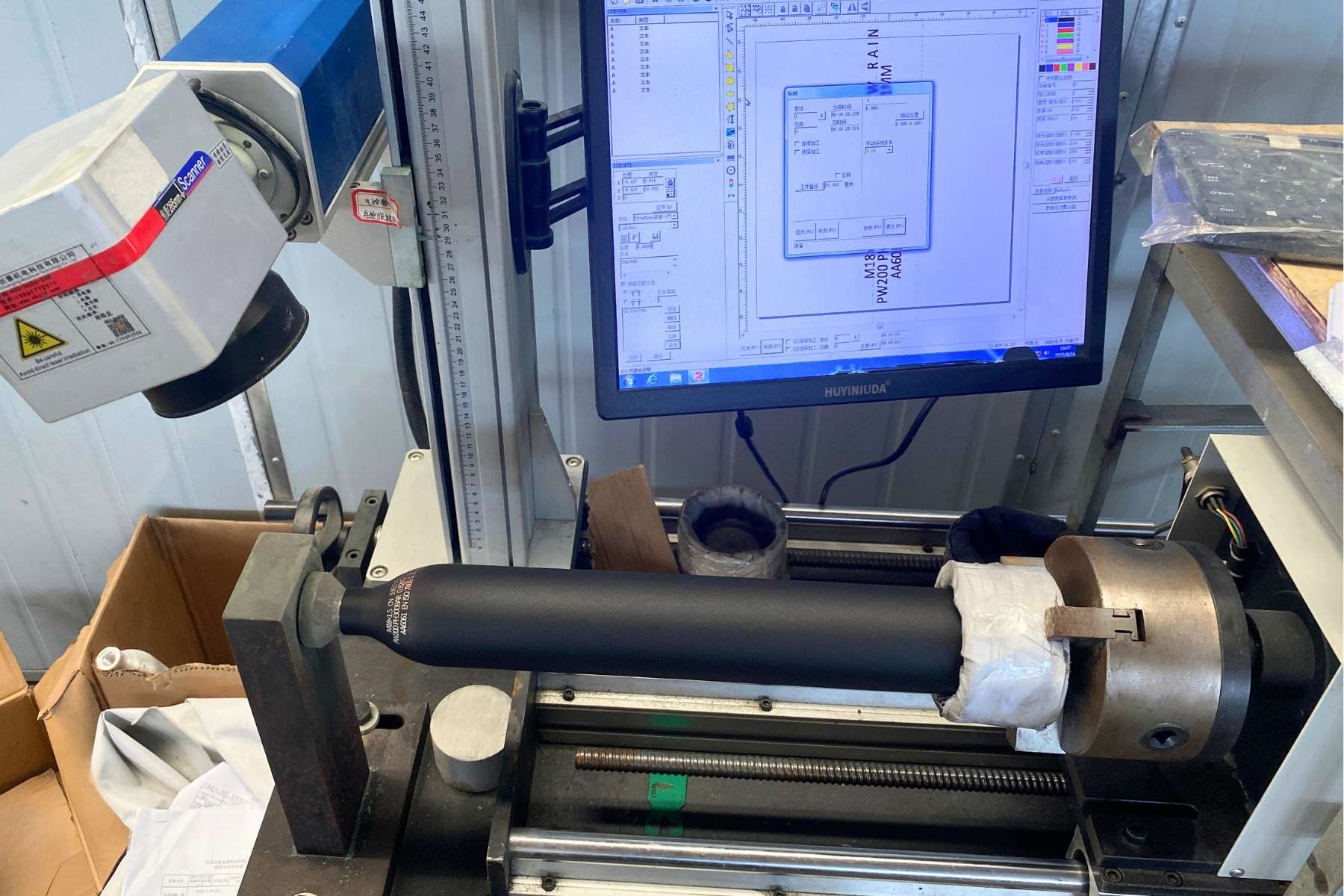

Some users' concerns about aluminum alloy PCP air cylinders often focus on safety. In fact, lightweight design does not equate to reduced strength, but rather achieves a balance of performance through reasonable material selection and structural design. During the production of aluminum alloy PCP air cylinders, Snowrain performs hydraulic testing, airtightness testing, and appearance inspection on every cylinder to ensure that the product is safe and reliable within the rated working pressure range, building the weight advantage on a controllable quality system.

For PCP shooting, the difference in air cylinder weight ultimately translates into a difference in shooting experience. Snowrain's aluminum PCP air cylinders offer a more comfortable solution for prolonged shooting and frequent use through optimized weight control. As a manufacturer specializing in aluminum alloy PCP air cylinders, Snowrain combines mature manufacturing processes and strict quality management to deliver lightweight, safe, and stable cylinders, providing reliable options for various applications.

If you are evaluating the weight differences of PCP air cylinders in practical use, or planning to select a more suitable aluminum PCP air cylinder for your project, Snowrain welcomes further discussion. We can provide technical advice based on your specific application needs and support factory visits to help you gain a firsthand understanding of the production process, testing procedures, and quality control system of our aluminum alloy PCP air cylinders, enabling you to make a more informed decision in the early stages of your project.